Restricting PFAS in engineering plastics

The European Chemicals Agency (ECHA) has recently published a proposal for a new REACH Annex XVII restriction on per- and polyfluoroalkyl substances (PFAS). This proposal expands the definition of PFAS to include over 10,000 chemicals, among them fluoropolymers such as PTFE and PVDF.

Fluoropolymers are used widely across many industries, and the restriction of these materials will have implications for many businesses. Mitsubishi Chemical Group - Engineering Shapes & Solutions Division is closely monitoring the progression of this proposed legislation and its significance for our global customers, production processes, and portfolio of materials containing fluoropolymers.

Until the scope of the new PFAS restrictions has been finalized, this page is meant to help customers who currently use engineering thermoplastics containing PTFE or PVDF prepare for the possibility of replacing these materials.

Below you will find information about what we know about the ECHA proposal, which materials are likely to be impacted, and how Mitsubishi Chemical Group can support customers in finding alternatives to PFAS materials.

-

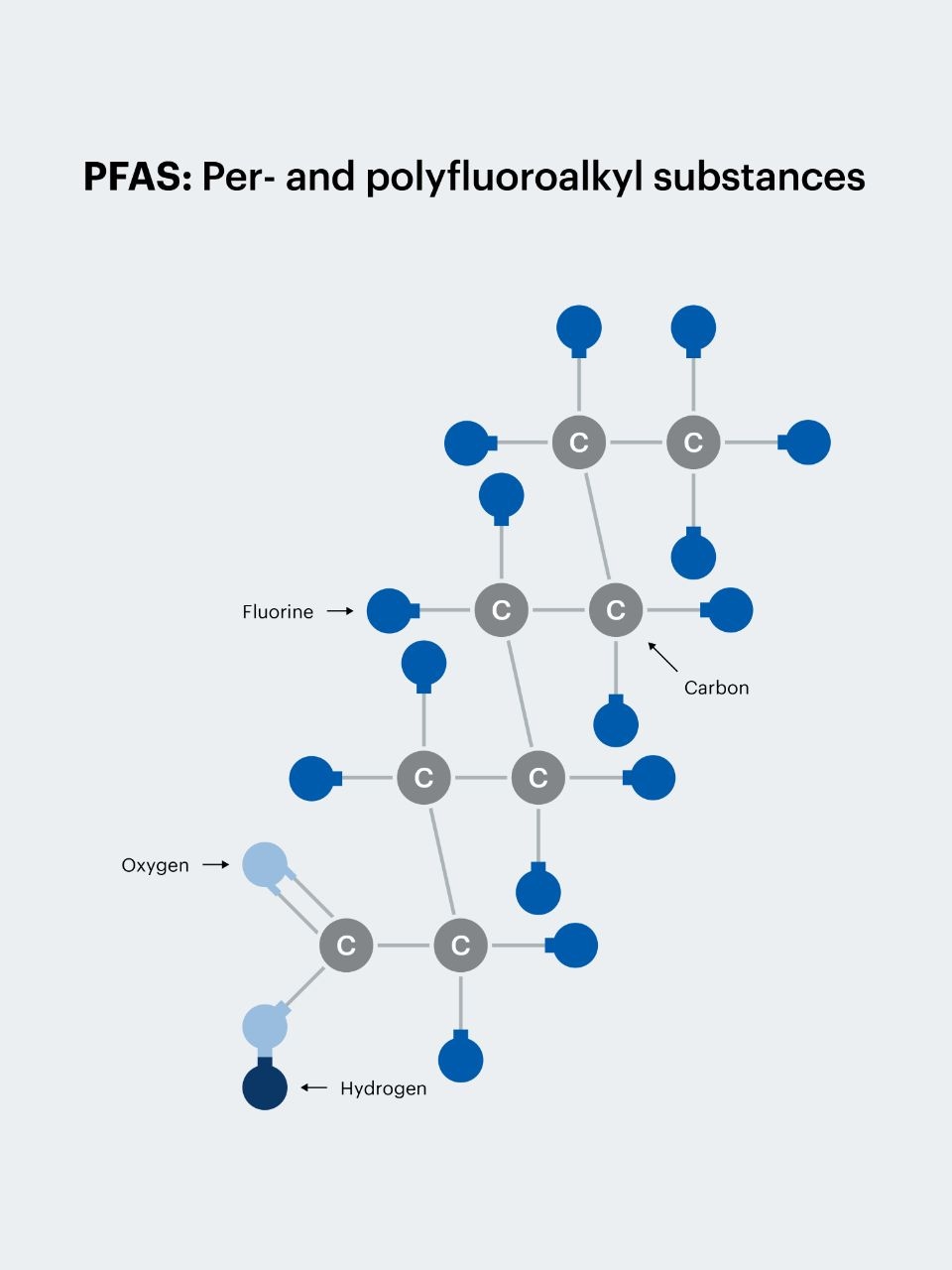

PFAS stands for per- and fluoroalkyl substances and refers to a large class of synthetic chemicals that contain at least one fully fluorinated methyl (CF3-) or methylene (-CF2-) carbon atom (without any attached H/Cl/Br/I).

Due to the extremely strong chemical bond between carbon and fluorine in PFAS chemicals, these substances resist degradation to an extreme degree. Their persistent characteristics, combined with their water solubility, make PFAS difficult to contain and dispose of, resulting in high levels of PFAS in soil as well as in surface, ground, and drinking water around the world. PFAS are sometimes referred to as “eternity chemicals,” as there is currently no efficient or cost-effective method for removing accumulated PFAS from the environment. Though not the case for all chemicals in this class, some PFAS have shown to be toxic to human health as well as the environment.

The ECHA proposal from February 7, 2023 aims to restrict the manufacture and use of PFAS chemicals in order to slow pollution from these substances and prevent their further accumulation in the environment. A full list of the now more than 10,000 substances subject to impending restriction is available on the ECHA website.

-

PFAS chemicals possess unique material properties that have found broad use in both consumer products and engineering, enabling critical applications that drive technological advancements.

Fluoropolymers such as PTFE and PVDF are highly resistant to chemical corrosion and high heat, making them suitable for extremely demanding engineering applications involving aggressive chemicals and temperatures. PTFE in particular is widely used for its extremely low coefficient of friction, which makes it an outstanding material for bearing and wear applications.

-

A number of engineering plastic stock shapes manufactured by Mitsubishi Chemical Group - Engineering Shapes & Solutions Division use PTFE or PVDF as a base material or contain PTFE or PVDF additives. Based on the current ECHA proposal, we anticipate that the following stock shapes are affected:

- Acetron™ AF Blend / Ertacetal™ H-TF POM-H

- Duratron™ PAI materials

- Fluorosint™ PTFE materials

- Duratron™ DF PI, Duratron™ DFU PI, and Duratron™ TX PI

- Ketron™ TX PEEK, Ketron™ HPV PEEK, and Ketron™ Sterra™ HPV PEEK

- Semitron™ ESD 500HR PTFE

- Semitron™ ESD HPV PEEK

- Ertalyte™ TX PET

- Techtron™ HPV PPS

At this time, we are unable to conclusively state whether this list of affected products is complete. We will continue to monitor developments in the proposal closely to keep this list up-to-date.

-

Due to the unique property profile of fluoroplastics, there is no single polymer with a composition that might replace it in every application. If you are looking to replace a PTFE- or PVDF-containing material, we recommend starting with a detailed analysis of the thermal, chemical, and mechanical requirements of your application. Furthermore, it should be noted that replacing the material of a part often results in the need to change its design as well.

Because we offer the market's broadest range of engineering plastic shapes, Mitsubishi Chemical - Engineering Shapes & Solutions Division is in a unique position to help you navigate the transition away from fluoropolymers. Beyond our portfolio of hundreds of materials without a fluoropolymer composition spanning diverse performance profiles, our technical services department is available to assist you with material selection, design considerations, and processing options.

-

For more information about ECHA's proposal to restrict PFAS substances, please refer to the Q&A section on their website.

Because materials like PTFE and PVDF are so widely used in both industrial and commercial products, the impending restriction of fluoropolymers will have sweeping consequences for many businesses. Mitsubishi Chemical Group is committed to supporting customers through this transition.

- Providing transparency about PFAS-containing products

- Introducing tools and documentation to help you quickly assess whether a product has PFAS in its composition

- Monitoring developments in ECHA and REACH restrictions on PFAS

- Consulting on material selection to help customers find suitable materials without PFAS in their composition

- Developing replacement materials with similar performance profiles

The sustainable wellbeing of people and the planet

Learn about KAITEKI, the philosophy that guides our company.

MatFind

Quickly find the optimal engineering plastic for your application. Simply input the performance properties you require, and MatFind will help you filter and compare materials.

The market's broadest portfolio of thermoplastic shapes

No matter the performance requirements of your application, you’ll find the material you need in our offering of semi-finished and custom thermoplastic products.

Looking for something specific? Get in touch with our specialist teams by filling in the contact form. We’re ready to meet your next challenge.

Contact us